Exploring Different Types of Printing Bindings

In the world of printing, the way a book or document is bound is as essential as the words and images within. The choice of binding method not only influences the physical form but also impacts the durability and overall reading experience. So, let’s dive into the fascinating world of different types of printing bindings.

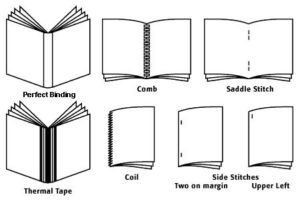

Saddle Stitching

Saddle stitching is a common and cost-effective binding method. It involves stapling sheets together through the fold and creating a booklet. This method is ideal for brochures, magazines, and booklets with a lower page count. While it offers a clean and professional look, it may not be suitable for thicker publications.

Perfect Binding

Perfect binding is widely used for paperback books. It involves gluing the pages to the spine, therefore creating a flat edge. This method provides a sleek and professional appearance, making it suitable for novels, catalogues, and thicker magazines. Perfect binding accommodates a higher page count compared to saddle stitching.

Spiral Binding/ Wire-O Binding

Spiral binding, also known as coil binding, involves inserting a plastic or metal coil through holes punched along the edge of the pages. This method allows the document to lay flat when open and facilitates easy flipping of pages. It is popular for notebooks, manuals, calendars and reference materials.

Comb/Cerlox Binding

Comb binding utilizes plastic combs that are threaded through punched holes along the edge of the pages. Easily add and remove pages with this type of binding. Comb binding is also commonly used for reports, presentations, and instructional manuals.

Case Binding

Case binding is a sturdy and durable method often associated with hardcover books. It involves sewing the pages together, attaching them to a cover board, and wrapping the cover with a printed or fabric material. This method is ideal for high-quality books, ensuring longevity and an elegant appearance.

Thermal Binding

Thermal binding uses heat to adhere pages to a cover. This method provides a clean and professional finish, making it suitable for documents, proposals, and presentations. Thermal binding creates a spine that adds a polished appearance to the finished product.

In Conclusion

The choice of printing binding method depends on factors such as page count, purpose, and desired aesthetics. Each binding type brings its unique characteristics, contributing to the overall look, feel, and durability of printed materials. Whether it’s the sleekness of perfect binding or the flexibility of wire-O binding, each method plays a vital role in binding the story within the pages.